The Of 24hr Media

Wiki Article

The smart Trick of 24hr Media That Nobody is Discussing

Table of ContentsThe Main Principles Of 24hr Media Some Of 24hr MediaThe Ultimate Guide To 24hr MediaThe 2-Minute Rule for 24hr Media24hr Media - Questions

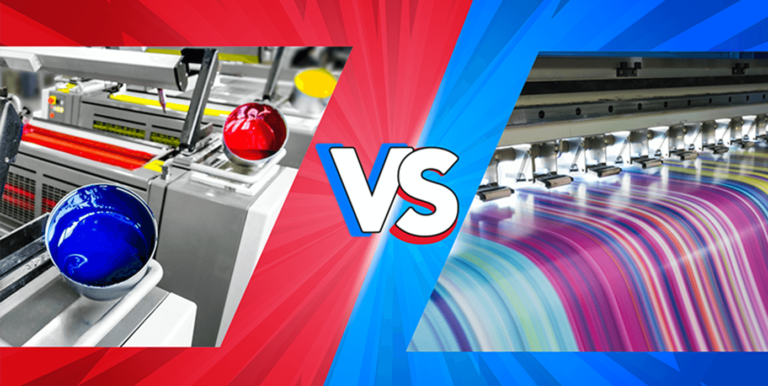

Developments in print innovation are altering the communications playing area when it involves quality, price and cutting-edge capacities. Countered printing and digital printing are the major procedures whereby print tasks are carried out both utilizing four-color printing approaches. Each alternative has its advantages, providing different strategies to satisfy the requirements of diverse manufacturing jobs.

Commonly, this has actually been one of the most regular strategy for exactly preserving color matches, making it ideal for print runs that only require fixed printing such as pre-printed kinds, sales brochures, leaflets, calling card, and bulk postcard mailings. Due to the static nature of litho printing, it is not suitable for variable print items that will be mailed to specific receivers such as statements, letters, and personalized postcards.

The Single Strategy To Use For 24hr Media

The current developments in print modern technology are helping to bring a number of countered's advantages into the electronic printing globe really altering the face of modern-day printing! There are some key differences in between Offset Printing and Digital Printing (Wallpaper). This overview reveals the advantages and negative aspects of each printing method. There is an indisputable and expanding variety of benefits to making use of the digital print process.

Today's digital print equipment is among the most cutting-edge on the market. Here are some of the biggest advantages of utilizing electronic printing: control the electronic print area, with full-color printing completed in one process and perfectly printed directly from a print documents. Without an extensive set up process, the calibration time of a particular task is shortened, contributing to quicker print time and total distribution.

The inkjet printing procedure has helped to revolutionize the industry along with the top quality and rate of the outcome. The most recent inkjet modern technology can publish on traditional balanced out stocks with dull, silk, and shiny surfaces. Top notch electronic print coupled with software-managed shade administration methods adds optimum value to publish pieces and makes manufacturing procedures extra trustworthy than balanced out.

Not known Details About 24hr Media

(https://za24media.mystrikingly.com/)Exact amounts of ink and toner are used to stay clear of waste. Environment-friendly and eco-friendly inks and toners are also available for even more lasting printing. Digital print likewise eliminates the requirement to wash plates or coverings with damaging chemicals at the end of the printing process. As the high quality of digital print solutions raises, the benefits end up being increasingly evident and valuable.

Variable data aids services reach their exact consumers and target market with uniquely-created and individualized web content. As innovation improves, the top quality of digital printing has actually ended up being second-to-none, with better detail, shade match capabilities and general precision. Without the requirement to wash plates or make use of excess ink, digital printing is additionally less inefficient and typically extra eco-friendly.

Standard printing approaches, such as countered lithography ("offset") and flexography ("flexo"), include multiple make-ready steps to move an original picture to a substratum. These techniques call for the production of a series of plates placed on a cylinder to transfer ink that creates the desired picture when incorporated on paperboard and other product packaging products. Small Volume Packaging.

Excitement About 24hr Media

While electronic printing is a viable option for a lot of short-run print workspecial occasions, prototyping, or other considerationsits modern abilities actually display in rapid turn-arounds. Being able to customize packaging via variable information printing has actually opened brand-new chances for you to engage with your consumers in more individualized methods. Digital printing, with fewer moving pieces, is more agile than offset in this respect.Minimized set-up time saves money on the front end. And since these are not substantial bulk orders, smaller organizations can pay for to print without having to fulfill the greater and more pricey print thresholds of typical printing.

Make sure you collaborate with a printing and product packaging partner that has the best qualifications. While eleventh-hour printing and customization are a huge advantage, digital may not always be the very best method for you. For instance, offset printing has the benefit of cost-effectiveness with large print runs, particularly those with advanced ornamental results and specialty coatings.

Indicators on 24hr Media You Need To Know

The favorable plate, with its smooth surface, draws in oil-based inks and repels water. In contrast, the adverse plate, with its rough structure, soaks up water and wards off oil. Rubber rollers are after that used to transfer the image from the plate to the corrugated surface.Corrugated paper can in some cases confirm to be a difficult surface area to print on, however Litho prints to a different surface area and is then laminated to it, making it very easy to publish premium photos. It can be extremely constant, also for futures. In fact, the more you publish, the more affordable the costs become for Litho.

If you have sufficient time and Get More Information spending plan, and a huge volume of a single design, then there shouldn't be an issue. What Litho doesn't provide you is precisely what Digital does, modification. Extra on that later. Expensive set up Longer turnaround No Variable Data Printing Smaller color gamut, colors can be less bright Digital printing is the process of printing digital images directly onto the corrugated substratum using a single-pass, direct-to-corrugate technique - Window Vinyl.

Report this wiki page